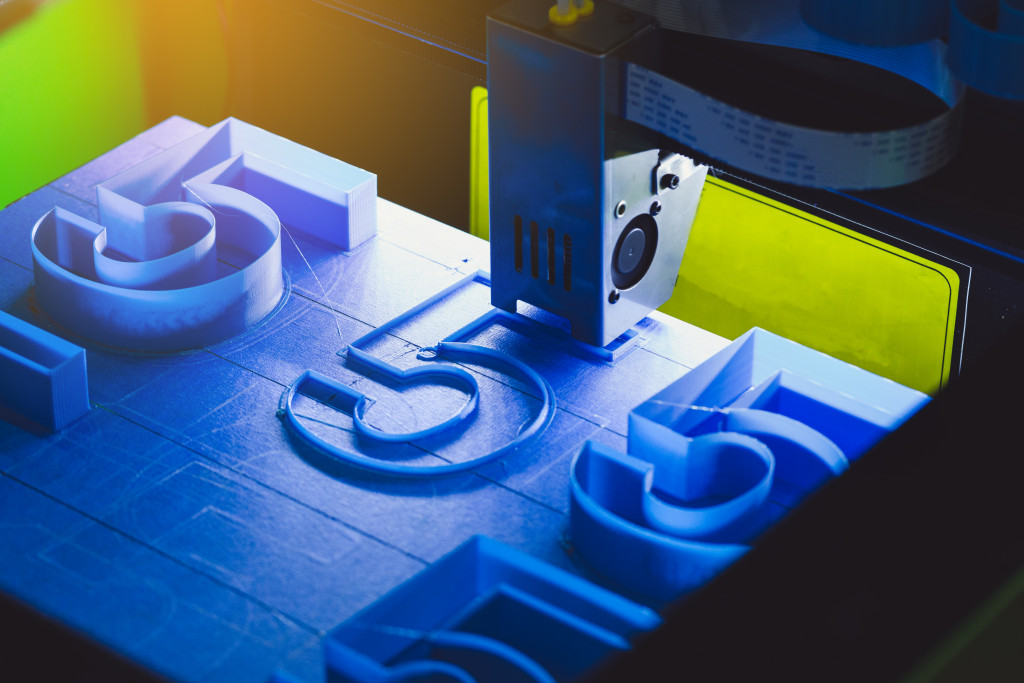

The concept of 3D printing has been around for decades, but only recently did it become part of the mainstream lexicon. For nearly 30 years, engineers and designers have been using large and expensive 3D printers to manufacture prototypes of parts in automotive, aerospace, and defense companies.

Now, however, more people have access to technology. Over the years, scanners have become ubiquitous in almost every business or home, and digital design software has improved so much. It is easier, and more affordable, than ever for self-starting entrepreneurs or hobbyists to manufacture anything they want.

Many believe that in the future, it will become more widely available. 3D printer manufacturers are making the technology accessible to any designer, engineer, entrepreneur, hobbyist, or even regular person who wants to take advantage of its numerous benefits.

Here is what the future will look like thanks to 3D printing:

Production of Rare Parts

Right now, consumers have to scour all possible retailers and sellers to acquire parts that may have long gone out of production or not available domestically. Repair shops will have the opportunity to restore any item, even if they have no access to replacement parts. All they need to do is print out the parts that were needed and install them on the device.

It is perfect for third-party repair shops that may not be authorized by manufacturers to fix devices. Apple, for example, has been blocking the Right to Repair legislation in the United States and has been making it impossible for independent repair shops to acquire necessary parts.

3D printing will also make fixing electronic devices more affordable. The cost of parts would not depend on the availability of supply, but size and complexity will be the factors considered in pricing.

Personalized Apparel

Consumers want customizable products, and 3D printing can enable them to alter a piece of clothing or accessory any way they want.

Customers no longer have to fuss over sizing. The machine will manufacture the product based on a real person’s unique measurements. Every time a customer makes a purchase, the product will suit and fit their physical features perfectly.

This enabled brands to make their customers a co-creator. The technology allows retailers to print belts, glasses, rings, or gloves that meet the customer’s own needs and preferences.

Food Production

3D printing creates endless possibilities for food services. Nowadays, people are eating an increasingly varied diet. Crafting a menu that can accommodate the needs and preferences of each potential customer can be a nightmare.

However, 3D printing can help by customizing the food being served. The technology can offer to alter shapes and textures, flavors, and nutritional content. It can be used to tackle public health threats such as obesity or malnutrition.

By manufacturing a chewable pod containing all the nutritional needs of a person, children in impoverished communities can be saved from illnesses that come with a poor diet. It can also be helpful for patients undergoing treatment and have a restrictive diet.

Moreover, professional chefs can also utilize the technology to more easily craft intricate structures for food presentation. It has the potential to reduce food waste, too, because establishments can use ingredients efficiently without throwing away any excess.

Healthcare

3D printing has a huge potential to improve healthcare in the coming years. At present, the technology is already being used to produce personalized and affordable prosthetics for millions of people who are in need of mobility aids. The technology allows healthcare workers to print devices designed to address a patient’s specific needs.

Scientists are also studying the use of 3D printing to produce tissues and organoids. The process, dubbed bio-printing, does not use plastic or metal; it utilizes living cells called bio-ink to create artificial but living tissues in a laboratory. These organoids can be transplanted into the human body and mimic the natural function of human organs.

The technology can also be used to manufacture sterile surgical instruments in-house and at a lower cost.

Space Manufacturing

It is no longer out-of-reach for the human race. In recent years, there has been an increased activity outside of Earth. More satellites are being launched every year, and, more recently, billionaires have started launching tourists into low-orbit. There are also plans to send humans to the Moon and then Mars in the near future.

But, for these missions to be successful, equipment will be needed. Instead of launching every necessary supply to space, there may come a time when astronauts will simply print out the tools, parts, food, or other things they need. It solves the problem of distance, and it will be cheaper in the long run compared to sending rockets to space regularly.

3D printing is still in its early stages. In the future, it will accomplish more to push technology and the human race forward.