- Embracing technology like CAD software and CNC machining can significantly improve efficiency in metal fabrication businesses.

- Automation, through robotics and automated packaging, enhances productivity while ensuring safety and reducing labor costs.

- Utilizing XRF analyzers and accessories ensures the quality of raw materials and protects investments.

- Successfully starting a metal fabrication business in the modern world requires adaptation to the latest technological trends.

Are you an entrepreneur looking to start a business in metal fabrication but not sure where to start? Look no further. With technology rapidly advancing, it is essential to embrace the latest tech in the industry to make your business stand out. Whether you are an aspiring metal fabricator or a seasoned professional, you can elevate your ventures by integrating these latest technology trends.

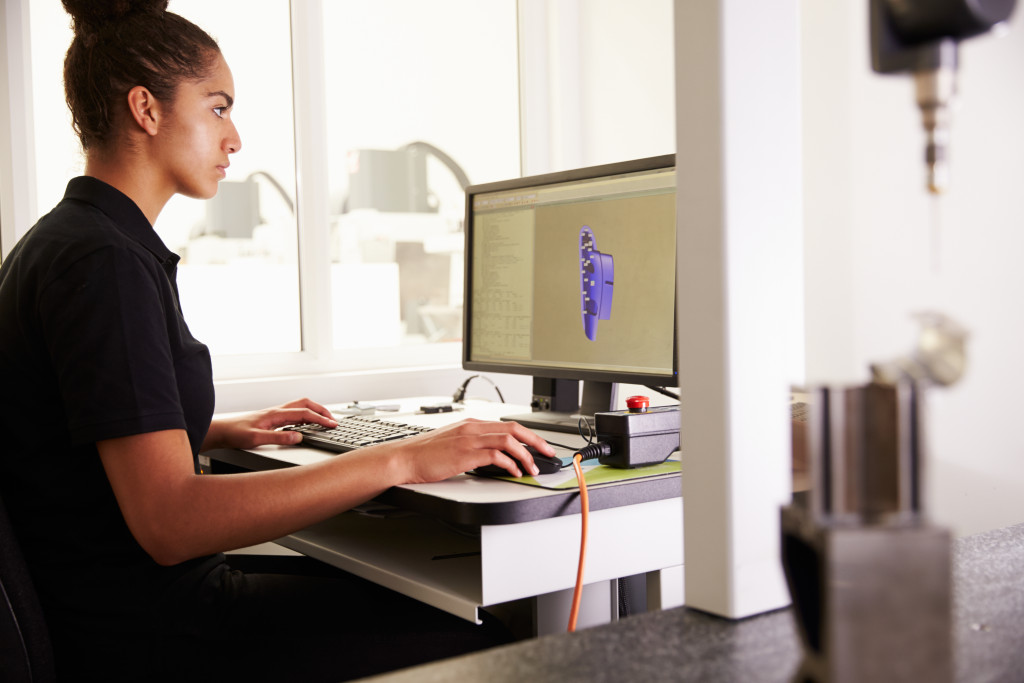

Utilize CAD Software

Computer-aided design (CAD) software is an essential tool for modern metal fabricators. It helps you create two-dimensional or three-dimensional designs using computer software.

With CAD software, you can design intricate and complex metalwork with ease. It also reduces the need for hand-drawn blueprints, making the entire process more efficient.

By utilizing CAD software, you can increase your productivity and improve the accuracy of your designs. In some cases, you can even create virtual versions of your designs to test for strength and durability before investing time and resources into the project.

Embrace Robotics

Automation is becoming increasingly popular in the metal fabrication industry and for a good reason. Robotics can perform repetitive tasks with precision and accuracy, reducing labor costs while increasing productivity. They can also handle heavy loads and work in hazardous conditions, ensuring the safety of your employees. With the latest robotic systems, you can achieve higher output and improve the quality of your products. Here are some examples:

Robotic Welding

Robotic welding is a pivotal component of advanced metal fabrication processes. They reduce the risk of workplace accidents and injuries, enhancing overall safety standards. Robotic welding systems can be programmed to perform different types of welding tasks, offering versatility that is unmatched by manual processes.

Automated Packaging

In the era of modern metal fabrication, automated packaging is a game-changer. Implementing automated packaging systems in your business operations can streamline the end-of-line process significantly. It simplifies tasks such as wrapping, palletizing, and labeling, reducing the time taken to prepare products for shipment.

CNC Machining

CNC (Computer Numerical Control) machining is another revolutionary technology for metal fabrication. It utilizes computers to control the machines’ movement, allowing for precise cuts and shaping of the metal. CNC machines can work on multiple projects simultaneously, saving you valuable time and increasing production capacity. By investing in CNC machining, you can achieve higher precision and efficiency, reducing waste and increasing profits.

Invest in XRF Analyzers

X-ray fluorescence (XRF) analyzers are a must-have for any metal fabrication business. This portable device is capable of detecting the chemical composition of various materials, such as aluminum, copper, and steel. With this tool, you can track the quality and authenticity of your raw materials in real time to ensure that they comply with standards. Here are some things you need to invest in for greater use of your XRF analyzers:

Portable Stand

Optimizing your workspace is crucial when running a metal fabrication business, and this is where a portable stand comes into play. The durable Niton XL2 portable test stand is an excellent companion for your XRF analyzer.

It provides a secure and stable platform for the device, ensuring accurate measurements and preventing any mishandling that could damage the analyzer. Its portability feature enables you to move it around your workplace, offering the flexibility to analyze materials wherever they are.

Charger

Battery life is a key consideration when using portable devices like XRF analyzers. To ensure uninterrupted operations, investing in a reliable charger is essential.

Chargers with fast-charging capabilities can quickly power up your analyzers, reducing downtime and improving productivity. Furthermore, chargers that offer overcharge protection features are recommended to prolong the lifespan of your equipment’s batteries.

Case

Protecting your investment in technology like the XRF analyzer is of utmost importance. A sturdy, durable case can be instrumental in safeguarding your analyzer from potential damage due to drops, shocks, or unfavorable environmental conditions.

Cases with additional compartments provide space for storing other accessories like chargers or portable stands. By selecting a case that is designed for your specific model, you can ensure a snug fit and optimal protection for your device.

Starting a metal fabrication business in the modern world requires you to embrace technology to stay competitive. By utilizing CAD software, CNC machining, robotics, cloud-based management systems, and keeping up with the latest trends, you can achieve higher productivity, efficiency, and accuracy. With technology’s help, you can take your metal fabrication business to the next level and stand out in today’s competitive market. So, embrace technology, innovate, and take the first step to success in metal fabrication.