- Investing in automation and robotics can improve efficiency, reduce labor costs, and increase task accuracy.

- Quality control is essential to maintain customer loyalty and produce high-quality products.

- Lean manufacturing helps streamline production processes and reduce costs while still maintaining quality.

- Accessible technology should be adopted to maximize the efficiency benefits of automation and robotics.

- Consult with experts to tailor advice specific to your business plan for successful implementation.

The pandemic caused a catastrophic decline in manufacturing output at an annual rate of 43 percent in 2020. It also caused hours worked to drop by 38 percent – the largest drop since World War II. From motor vehicle production to food and beverage, virtually all major industries were affected by these staggering declines with no exemptions.

If you’re a business owner, chances are you’ve thought about ways to increase revenue for your factory. But with so many ideas, it can be hard to know what will work and what won’t. To make matters even more confusing, many strategies that appear to be the most effective cost a lot of money upfront. This blog post will explore how to increase revenue in your factory without breaking the bank.

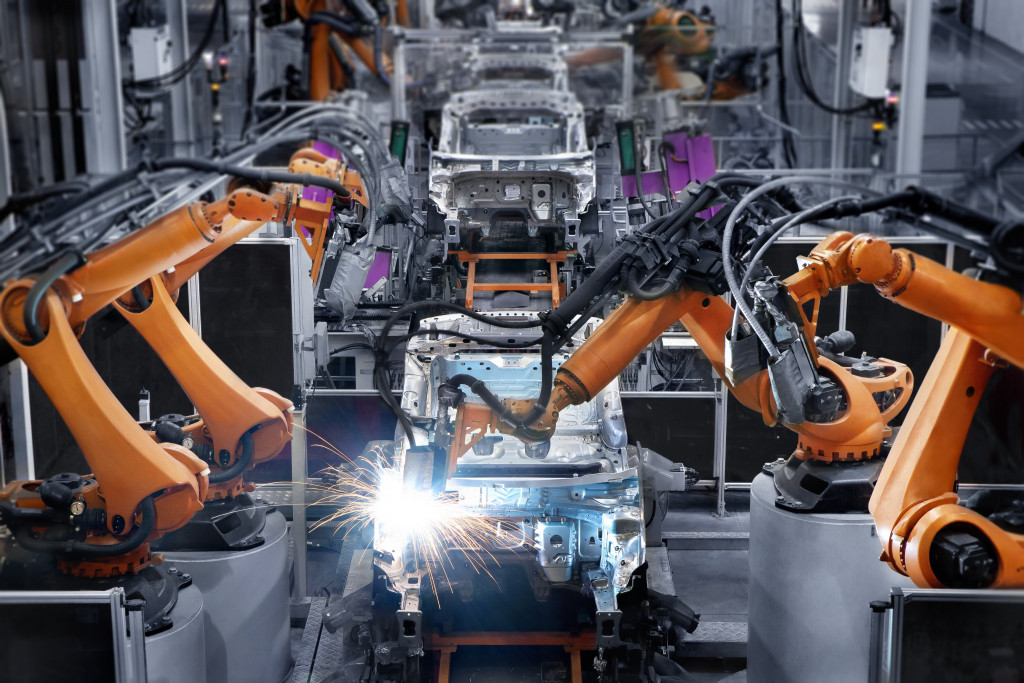

Invest in Automation and Robotics

One of the most popular ways to boost efficiency and productivity is by investing in automation and robotics. Automation can automate certain processes, such as packaging, sorting, and labeling, that typically require manual labor. This not only increases output but also reduces labor costs.

Safety and Efficiency

Additionally, robots can help with tasks like welding and assembly, which can be difficult or dangerous for human workers. Investing in automation and robotics is a great way to increase efficiency without hiring more people or spending more money on resources. Furthermore, automation and robotics can help to reduce errors and improve accuracy in tasks which further adds to the overall efficiency of a business. By utilizing these tools, businesses can achieve better results at a lower cost.

Operational Efficiency

Investing in automation and robotics can also help businesses to streamline their operations. To facilitate this, you should install reliable motion motor systems to facilitate accurate motor position. The system should also be scalable to make them suitable for any equipment in the factory. Using the system reduces operational costs while increasing efficiency in the factory.

Accessible Technology

Finally, when it comes to automation and robotics, businesses must invest in accessible technology. That means investing in systems that can be easily integrated with existing software solutions and are easy for workers to use. By making sure the technology is user-friendly, businesses can maximize its efficiency benefits without having to spend a lot of resources on training employees to use the system.

Focus on Quality Control

Quality control is an essential part of any factory’s success. Many businesses don’t realize that poor quality control leads to higher costs due to waste and product damage. On top of that, it also affects customer loyalty which translates into lower sales numbers.

Meet Standards

By investing in quality control systems, you can ensure that products meet high standards before they leave the factory floor. This will help maintain customer loyalty and increase sales over time. Quality control should be a priority for any factory, and investing in the right systems will allow you to ensure that each product is of the highest quality.

Streamline Process

Additionally, having a well-functioning system can help streamline production processes, leading to more efficient operations and higher productivity. Quality control should never be overlooked as it’s the key to producing high-quality products that customers will be proud to own. Investing in quality control systems and processes can help guarantee customer satisfaction and a more profitable business.

Implement Lean Manufacturing Practices

Lean manufacturing is a process improvement methodology aimed at reducing waste while increasing efficiency and profitability. Focusing on streamlining production processes and eliminating non-value-adding activities can reduce business costs while maintaining high levels of quality.

Areas for Improvement

These manufacturing practices, such as just-in-time inventory management or process mapping, can help you identify areas where processes can be improved so you can maximize your profits without investing too much money upfront. Additionally, by creating a culture of continuous improvement, organizations can quickly adapt to changing customer needs and remain competitive in the market. Adopting lean manufacturing principles will help your company become more agile, efficient, and profitable.

Increasing revenue in a factory doesn’t have to mean spending a lot of money upfront for new equipment or hiring additional staff members. It requires strategic planning and implementation of effective processes such as automation and robotics, quality control systems, or lean manufacturing practices. When done correctly, these measures can help you save time and money while boosting output at the same time! As always, when making significant changes like this, it is essential to consult with experts who specialize in business process optimization and who could offer tailored advice specific to your situation. Taking their advice could be beneficial if you wish to successfully implement these strategies into your business plan!